Description: Universal Energy Saving QZ2-80E12 Refrigerator Compressor PTC Start Relay Motor Starter For Haier Hisense Wanbao Homa RoyalStar FRESTECH etc. You Can Also Take Apart The PTC Starter To Use The Good PTC Chip With Your Old Stater'S Housing. As long as they look the same or similar,they can be used for your device! ----- If your compressor is not starting,But burning hot and "click-clack" about Every 3-5 Minutes When Powered On. It could be the start relay that is causing the issue. It is a simple process to replace. Let me know if you have any questions. Usually The PTC Sarter is about 4-50 Ω,When you tested it,if it's Not Good it will be more than 50Ω Or More. This fits many brands including Whirlpool, Magic chef, Samsung, Kenmore, Maytag, Haier, Danby and many others. Allows a Universal Energy Saving QZ2-80E12 Refrigerator Compressor PTC Start Relay Motor Starter For Haier Hisense Wanbao Homa RoyalStar FRESTECH etc. You Can Also Take Apart The PTC Starter To Use The Good PTC Chip With Your Old Stater'S Housing. As long as they look the same or similar,they can be used for your device! ----- If your compressor is not starting,But burning hot and "click-clack" about Every 3-5 Minutes When Powered On. It could be the start relay that is causing the issue. It is a simple process to replace. Let me know if you have any questions. Usually The PTC Sarter is about 4-50 Ω,When you tested it,if it's Not Good it will be more than 50Ω Or More. If You test the 2 pin holes,it will be more then 1k ohm,Due to it's a Low power starter with a special energy-saving diode bridge structure.Testing resistance like this doesn't make much sense. If you have questions we can tell you the right way to test it's Resistance. This fits many brands including Whirlpool, Magic chef, Samsung, Kenmore, Maytag, Haier, Danby and many others. Allows a simple repair to a common problem with many wine fridges, mini fridges, and beverage coolers. PTC Chip's Tested Resistance is about 5 Or 16-18 Ω. The Number and Characters on the Unit,Have No Practical Significance,Just For Reference! Please confirm from the specifications in the listing that if this item will be compatible with your device before you placing order. If you have any inquiries or questions please don't hesitate to contact us before purchasing,Thank you! We Also Have the PTC Starter: QP2-33, QP2-22, QP2-15,QP2-12,QP2-4.7,... Package Included: 1x Universal PTC Start Relay ----( Random Type Will Be Sent Out ) Electronic power consumption-free PTC (Positive Temperature Coefficient) starter an electronic power consumption-free PTC (Positive Temperature Coefficient) starter. A PTC thermistor and a bidirectional silicon controlled are connected in series; meanwhile, one end of the PTC resistor and the G electrode of the bidirectional silicon controlled are connected with a control panel in parallel; the control panel is composed of a rectifier bridge, a capacitor and a resistor; the capacitor and the resistor are connected in parallel between the cathode and the anode of a rectifier bridge; and the alternating current end of the rectifier bridge is respectively connected with the G electrode of the bidirectional silicon controlled, the PTC thermistor and the connection terminal of the auxiliary winding of a compressor. The bidirectional silicon controlled is controlled by the charging characteristic of the capacitor to be triggered to be switched on and off so as to achieve the purpose of controlling current flowing through the auxiliary winding, thereby thoroughly solving the technical problem existing in the commonly-used starter that the auxiliary winding of the compressor and the starter still have power consumption in the normal operation stage after the compressor is started, and realizing the purpose of no power consumption in the true sense. Description The refrigerant compressor starter circuit now widely used are the following :( a) shown in FIG. 3 with the auxiliary winding to start functioning at compressor start circuit includes a compressor ordinary PTC starter 2, in the steady operation with the main winding. 1, PTC resistor (i.e., a positive temperature coefficient thermistor) connected in series with the auxiliary winding 3, the start of the compressor due to the low temperature resistance of the PTC resistor 3 small, then there is considerable the current flowing through the PTC resistor compressor 3 through the auxiliary winding 2, with time due to generation of heat resistance 3 PTC resistance increases with increasing temperature, so that the current flowing through the auxiliary winding is reduced, but the PTC the resistance of resistor 3 is not infinitely increased, the compressor in normal operation of the circuit of the auxiliary winding is still a certain current, so that a certain power, it is unnecessary wastage. (B) shown in Figure 4 with a start saving type compressor starter circuit when the compressor starts functioning auxiliary winding 2 of the main series PTC resistor 3, 4 triac, controllable bidirectional while the control electrode G 4 in silicon (i.e., control electrode) and an end of the main PTC resistor 3 connected in parallel to the sub-PTC resistor 5, the current in the starter to start the compressor flows through the PTC resistor 5 sub-trigger triac , so that the main part of the compressor start-up current flows through the auxiliary winding. 3 PTC shunt resistor, with the increase of the extension of time such that the temperature of the PTC resistor increases the resistance of the current through the auxiliary winding decreases, the same principle because the sub PTC resistor 5 such that the increased resistance to flow through electrode G of triac current decreases, when the current is insufficient to trigger the triac triac is turned off, so that the main power of the PTC resistor does not generate power 3 consumption, but in the PTC resistor 5 and the sub compressor the auxiliary winding is still a relatively small current, so there is still some waste of power consumption. SUMMARY The object of The Start Relay is to overcome the drawbacks present in the prior art, to provide the normal operation after the startup phase to a compressor with virtually no power consumption of the compressor without electronic starter. The purpose of The Start Relay of are: start of the compressor is still in effect when the auxiliary winding 2 connected in series starter manner, in particular by a positive temperature coefficient thermistor, triac trigger circuit triggering circuit control plate composed of a positive temperature coefficient thermistor and a triac connected in series to the auxiliary winding of the compressor, the auxiliary winding connected in parallel between the positive pole connection terminals and the compressor temperature coefficient thermistor and the triac G a control plate trigger circuit the trigger circuit, the trigger circuit is a trigger circuit controlled rectifier bridge plate, capacitors, resistors, and alternating between positive and negative terminals of the rectifier bridge parallel capacitance, a resistor, a rectifier bridge connected to the end of the respective triacs G electrode and a positive temperature coefficient thermistor is connected to the auxiliary winding of the compressor end, the trigger circuit the trigger circuit directly control plate controls the triac is turned off, so as to control the current through the secondary winding, thereby controlling start power's. The Start Relay is not electronic power PTC starter circuit, using a trigger circuit board 4 instead of PTC resistor connected in series by a main triac port 4, while the triac control electrode 4 (G) and 3 is an end of the main PTC resistor connected in parallel with the energy-efficient resistor PTC sub starter sub PTC resistor, cleverly designed to positive, negative terminal connected in parallel between the capacitors, resistors, an AC terminal of the rectifier bridge of the rectifier bridge are each connected to a bidirectional controlled silicon electrode G and a positive temperature coefficient thermistor is connected to the compressor and the auxiliary winding terminal of the circuit, by the charging characteristics of the capacitor is controlled triac trigger turn on and off, into 3 to achieve the purpose of controlling the current flowing through the auxiliary winding, completely solves the problems of the current widespread use of starter technical problems still exist on the compressor power consumption and the auxiliary winding starter after the compressor starts running stage, to achieve a true no power in the sense of providing a guarantee for the device to maximize the energy efficiency rating of the compressor. BRIEF DESCRIPTION FIG. 1 is an embodiment of an electronic embodiment of The Start Relay, no power PTC starter circuit schematics [0007] FIG. 2 is an embodiment of an electronic embodiment of The Start Relay, no power is applied in principle PTC starter starting circuit of the compressor of FIG. FIG. 3 is now equipped with the technology of ordinary PTC starter circuit diagram of a start of the compressor FIG. 4 is equipped with the current art energy-saving compressor start circuit diagram of a starter Detailed ways The following embodiments in conjunction with embodiments of The Start Relay will be further described, the following examples only aspect of The Start Relay, The Start Relay is not limited. Example Electronic shown in FIG 1 PTC starter no power, it is mainly used to start the refrigeration compressor, the compressor windings Y normal operation of the main winding 1 and auxiliary winding 2, heat generated by the starter positive temperature coefficient sensitive resistors 3, 4 triac trigger circuit board consisting of P, positive temperature coefficient thermistor is connected to the auxiliary winding 2 of the compressor 4 groups 3 and triac in series, the positive temperature coefficient thermistor 3 the auxiliary winding of the compressor and the G 2 terminal is connected between the poles of the triac 4 parallel trigger circuit board P, the flip-flop circuit board P by the bridge rectifier 6, capacitors 7, 8 composed of a resistor, a rectifier bridge 6 positive, negative terminal between parallel capacitor 7, resistance 8, the AC terminal of the rectifier bridge 6 are each connected triac G electrode and a positive temperature coefficient thermistor 4 of the compressor 3 and the auxiliary winding connection terminals 2, a trigger circuit board P direct control of the triac 4 is turned on and off, so as to achieve through the secondary current of the control winding. When the compressor 2 is turned on the power switch 10 and the thermostat 9 is closed the current through the compressor started auxiliary winding 2, the rectifier bridge to 6, the capacitor 7 triac trigger 4 is turned on, so that can be thyristor 4 in an energized state, when the current through the start portion of the compressor 4 and the triac PTC resistor flows through the auxiliary winding 23, and also starts charging capacitor 7, with the time in the start time of the compressor 7 constantly charging capacitor, the capacitor voltage rising charge current gradually decreases, when the current is reduced to below the trigger current of the thyristor 4 or less than 4 so that the holding current of the thyristor is automatically turned off, the compressor startup end, this time in a stable operation of the compressor stages, compressor current all through the main winding 1. When the thermostat is disconnected the compressor is stopped, some of the resistor 8 starts when the capacitor 7 is discharged, so that the potential difference is generated across the capacitor to the starter to start again, when the capacitor discharge is completed, the starter has been restored, wait after the thermostat closes the compressor starts again. Briefly: When the power supply 10 to load the compressor, temperature control switch is closed to start the compressor to complete the triggering of the triac is turned on, the compressor start-up procedure implemented by the charging of the capacitor 7; when the temperature-dependent switch 9 after disconnection recovery program implemented by the discharge process of the starter resistor 8 of the capacitor 7, ready for the next start a compressor. Capacitor charging time is the start time of the starter start of the compressor, and the time of capacitive discharge resistor is the recovery time of the starter. The capacitor charging is completed, the triac is turned off automatically after the compressor is started into the normal operation phase of the program ends, there is no way back to the auxiliary winding current flows in normal operation of the compressor stage, the starter and the compressor so that the auxiliary winding is not generating power. [0016] compared to that shown in the application of more current now, less energy-saving power starter i.e. FIG. 4, the present embodiment to a trigger circuit board 4 instead of the sub-PTC resistor 5, and a compressor startup program end into the normal operation phase, the auxiliary winding back road no current flows in the normal operation of the compressor stage, eliminating the power generated by the deputy PTC resistor 5, achieved without power in the true sense.

Price: 24.99 USD

Location: Guang Dong

End Time: 2024-08-16T10:01:01.000Z

Shipping Cost: 0 USD

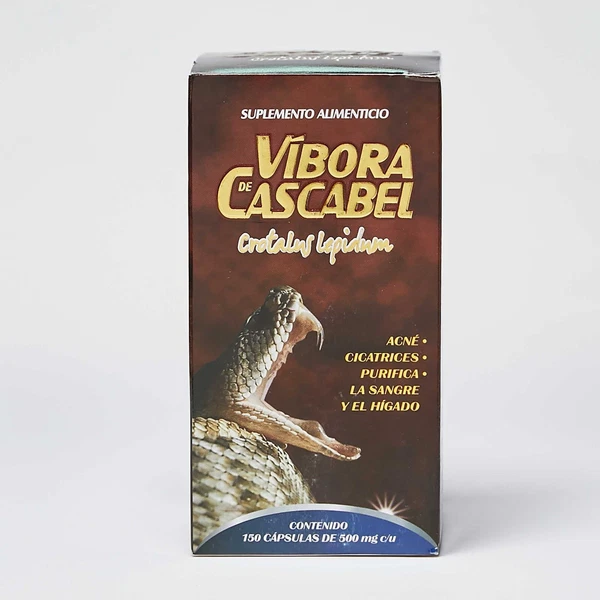

Product Images

Item Specifics

Return shipping will be paid by: Buyer

All returns accepted: Returns Accepted

Item must be returned within: 30 Days

Refund will be given as: Money back or replacement (buyer's choice)

Return policy details:

Type: Start Relay

Brand: Unbranded

MPN: QZ2-80E12

Compatible Brand: For Whirlpool, Universal Parts, Haier, Ronsheng, RoyalStarr, FRESTECH, Hisense, Combi, Fagor

Model: QZ2-80E12